As South Africa's best and only facility of its kind, the Rotating Machines (RM) Laboratory at the SABS boasts an impressive track record of delivering reliable and accurate test results. Testing electric motors and power tools ensures they are safe, efficient, and reliable, ultimately protecting users and enhancing efficiency.

Our expertise lies in testing electrical rotating machines to stringent international and national standards, specifically:

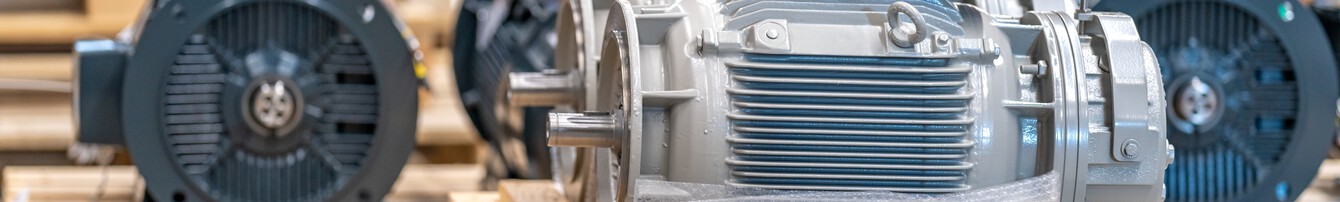

Motors

SANS/IEC 60034-2-1 and 60034-30-1 (Electric motor efficiency - IE1, IE2, IE3 and VC 9113)

SANS/IEC 60034-2-1 and 60034-30-1 (Electric motor efficiency - IE1, IE2, IE3 and VC 9113)

SANS/IEC 60034 series (International Electrotechnical Commission)

SANS/IEC 60034 series (International Electrotechnical Commission)

SANS 1804 series (South African National Standards)

SANS 1804 series (South African National Standards)

SANS/IEC 60072 series (International Electrotechnical Commission)

SANS/IEC 60072 series (International Electrotechnical Commission)

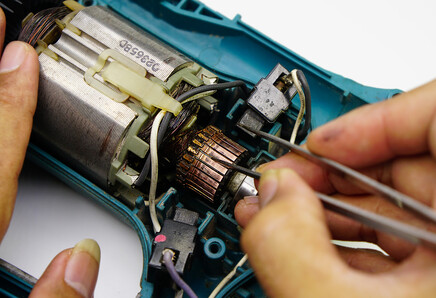

Power tools (battery and mains operated)

SANS/IEC 60745: Safety of handheld power tools

SANS/IEC 60745: Safety of handheld power tools

SANS/IEC 60335: Safety of household electric appliances

SANS/IEC 60335: Safety of household electric appliances

SANS/IEC 62841: Safety requirements for power tools

SANS/IEC 62841: Safety requirements for power tools

SANS/IEC 61029: Safety of transportable motor-operated electric tools

SANS/IEC 61029: Safety of transportable motor-operated electric tools

We offer the following testing services:

Testing motors from 0,37 kW up to 80 kW and in the process of improving capacity to 400kW e.g. New Three Phase, Single Phase Motors, Repaired Motors.

Testing motors from 0,37 kW up to 80 kW and in the process of improving capacity to 400kW e.g. New Three Phase, Single Phase Motors, Repaired Motors.

comprehensive testing of transportable, handheld and household motor operated power tools up to 2,5 kW (single phase) and 4 kW (three phase) e.g. drills, grinders, lawnmowers, lawn trimmers, mitre saws, shears, sanders and engravers.

comprehensive testing of transportable, handheld and household motor operated power tools up to 2,5 kW (single phase) and 4 kW (three phase) e.g. drills, grinders, lawnmowers, lawn trimmers, mitre saws, shears, sanders and engravers.

Our team offers comprehensive testing services, including Efficiency testing, Performance testing, Safety testing, Vibration analysis, Noise testing, temperature rise, etc.

SANS/IEC 60034-2-1 and 60034-30-1 (Electric motor efficiency - IE1, IE2, IE3 and VC 9113)

SANS/IEC 60034-2-1 and 60034-30-1 (Electric motor efficiency - IE1, IE2, IE3 and VC 9113)