The South African Bureau of Standards (SABS) is the only organisation in South Africa that is able to test for slip resistance in occupational and safety footwear. The state of the art machine that tests for slip resistance under various conditions was procured and operational since 2015. The safety of footwear can be validated via tests in accordance with South African National Standards (SANS), specifically SANS 20245:2014.

In some industries, such as construction and mining, it is a safety regulation that footwear cannot slip beyond a certain specification. The potential of slipping can cause severe injuries, broken bones and even death, depending on the environment and nature of the slip. Oily, greasy or wet environments require a higher degree of slip resistance than field workers or workers that need shoes designed for easier movement. The degree of slip resistance on safety footwear is required and in most industries is a compulsory basic requirement.

To ensure that footwear meets the safety and slip resistance requirements, footwear needs to be tested and the results independently verified and validated. Industries and workers who purchase safety footwear need to be able to ensure that slip resistance is tested and indicated, for safety and legal reasons. Slippage requirements differ for industries and these specifications are contained in various SANS. SANS are developed by various industry bodies and public representatives to ensure that SANS are aligned to internationally accepted standards and include South African requirements.

Slip resistance can be tested with specific equipment and in a laboratory environment. SABS regularly calibrates its test equipment to ensure that test results are accurate and valid. It is important to bear in mind that slip resistance is usually one element of a multitude of tests that include comfort and other safety features.

Some of the common types of tests that are conducted on footwear include: slip resistance; abrasion resistance; compression of toe caps; impact on toe caps; anti-static tests; interlayer bond strength; tensile strength; tear strength; flexing of upper (leather and gumboots); water vapour permeability and coefficient; and hydrolysis. These tests are done to specifications contained in various standards such as SANS 20344-7: 2014 Personal Protective Equipment; SANS 421:2017; SANS 942: 2016; SANS 1492: 2015; and SANS 1482: 2016. SANS are available for purchase via www.sabs.co.za

Following a business decision in 2015 to stop ‘partial testing’, the organisation has revised its approach to include a risk based implementation of customer specific requirements (CSR). This approach will ensure that manufacturers are able to test modifications of products to SANS or for specific manufacturing specifications, or for tendering purposes. SABS has been in talks with various organisations within the footwear, textile and leather industry and are currently developing more responsive service models to ensure that industry needs are met more effectively.

In addition to revising the business model, SABS will be encouraging internships and workplace learning opportunities so that young learners are able to learn about testing in the industry. Safety footwear is 100% designated area for local content and SABS is the state appointed organisation to provide these verification services. SABS also provides consignment inspection services to ensure that batches of products are made and delivered to specifications.

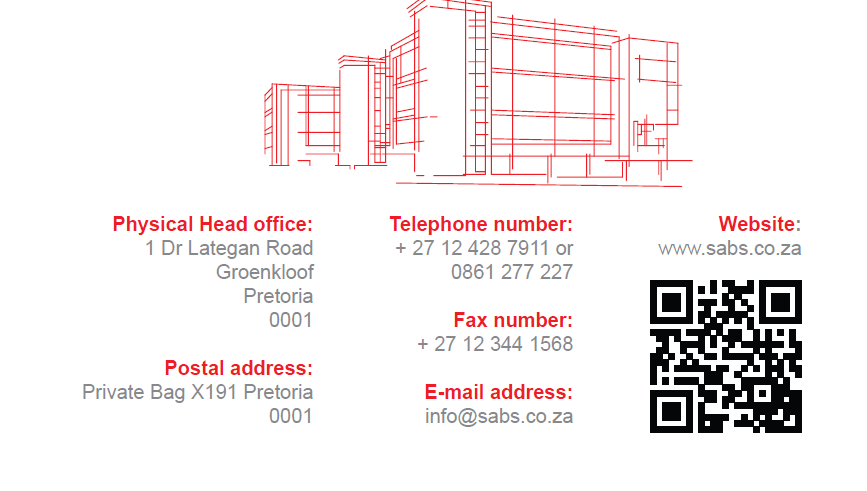

Contact us: